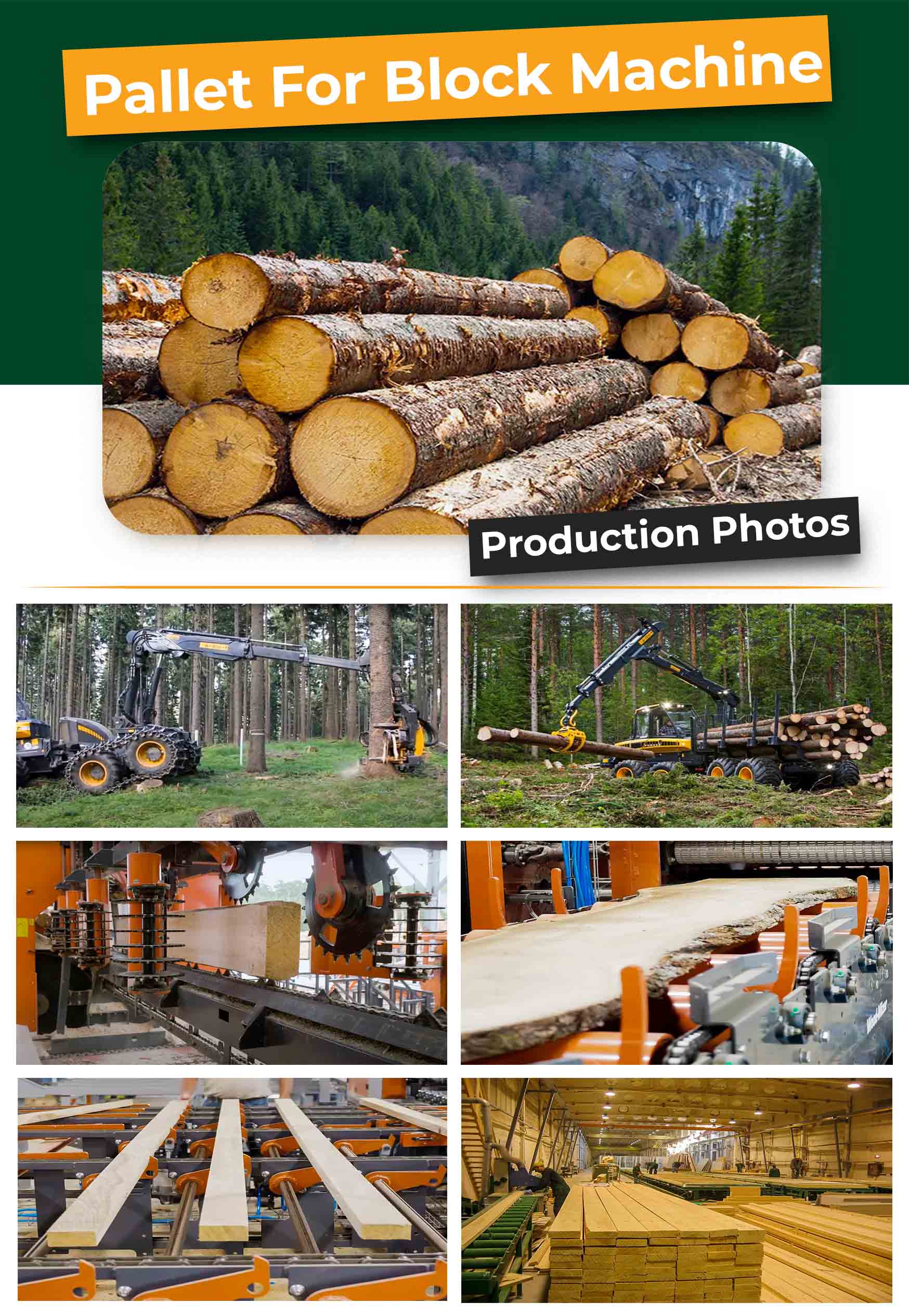

From Logs To Wooden Pallet

Log cutting is a critical step in the production of high-quality wooden pallets, especially for concrete block machines.

The selection and cutting of logs must be carried out with precision to ensure that the resulting pallets are durable and fit for purpose. Below, we outline key factors to consider during the log-cutting process and why it’s essential for the quality of wooden pallets used in block and paver block machines.

Read our blog “What Kind Of Wood Should Be Preferred For Pallet Production?” to learn more about the trees used in the production of wooden pallets.

Production Steps

The selection of high-quality logs with the correct moisture, diameter, length, and straightness is the first step in the log-cutting process. The procedure of cutting logs can be done manually or using automatic cutting equipment.

After the initial selection of high-quality logs, ensuring they possess the appropriate moisture content, diameter, length, and straightness, the log-cutting process moves into its next phase.

The Importance of Log Cutting in Wooden Pallet Production

“Quality and durable pallets are vital for safe concrete block production and storage operations.” This statement underscores the importance of every step in the production process, starting with log cutting. The way logs are cut directly impacts the strength and longevity of the pallets, making it one of the most crucial stages in the manufacturing process.

Key Factors in Log Cutting

The first step in the log-cutting process is the careful selection of high-quality logs. These logs should possess the correct moisture content, diameter, length, and straightness. Once selected, logs can be cut either manually or using automatic cutting equipment.

- Manual Log Cutting: Manual cutting involves skilled workers using traditional tools such as chainsaws, axes, or sawmills. This method requires a high level of expertise to ensure that each log is cut with precision, maintaining consistent quality throughout the process.

- Automatic Log Cutting: Automated cutting equipment, such as bandsaws or CNC (Computer Numerical Control) machines, is programmed to execute precise cuts based on specific requirements. This method enhances productivity, minimizes human error, and results in more uniform and accurate cuts.

The cutting of the logs must be done precisely and correctly. Defects should be inspected, appropriately dimensioned and beveled after the log-cutting process.

Ensuring precise log cutting is essential for quality lumber. After cutting, defects must be identified and addressed through dimensioning and beveling. Precision in cuts maintains structural integrity and facilitates assembly. Proper handling and storage prevent moisture-related issues. Overall, attention to detail yields high-quality lumber and timber products.

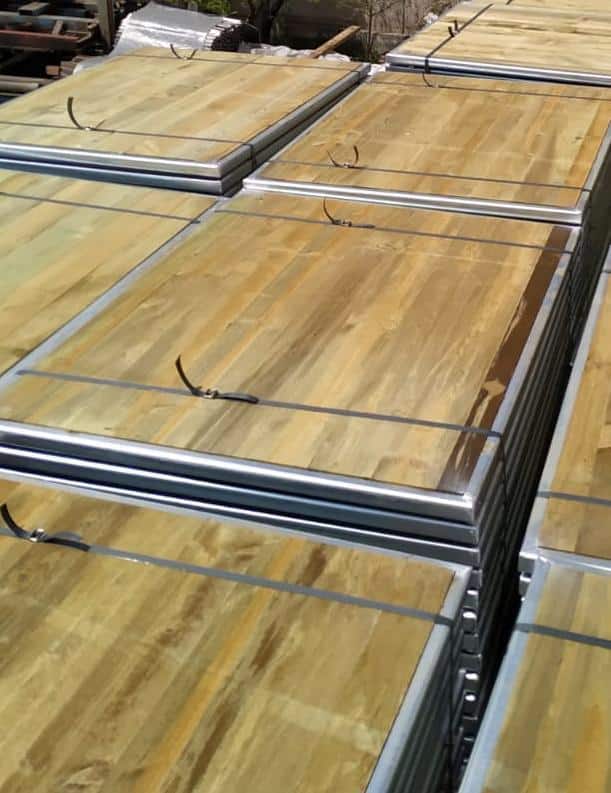

Installing metal frames or sheets to reach maximum durability and long-lasting.

Installing metal frames or sheets enhances durability and longevity. Metal components provide robust structural support, resisting wear and tear over time. This ensures that the installation remains sturdy and reliable, even in challenging conditions. By opting for metal frames or sheets, you can maximize the lifespan of the structure, reducing the need for frequent maintenance and repairs.

As a result, we need to consider about the moisture level which must be adequately managed and checked on a regular basis. Furthermore, proper storage of sawn logs is critical for the production of high-quality wooden pallet.

Excessive moisture content can weaken the structural strength of wood. Wet wood is softer and less durable than properly seasoned or dried wood. High moisture levels can also reduce the wood’s hardness, making it more susceptible to damage from impact or compression.

In applications where strength and stiffness are critical, for example, a wooden pallet has extreme pressing pressure to form a solid concrete block, and pallets without sufficient strength can become unusable.

Storing wood products in areas that have high moisture or wet conditions can lead to a possible risk of rotting or fungal growth. This is why sawn logs must be stored with appropriate care. Being a manufacturer, we strive to supply our clients with high-quality, long-lasting pallets at a reasonable price.

Therefore, as result, we use extreme caution when cutting logs for the production of Concrete Block Machine Pallets. Based on the right selection of logs, the right cutting method, the right moisture content, and the right storage methods we ensure the production of high-quality and durable wooden pallets.

Wooden pallets with metal profiles provide efficiency and durability for concrete block machines.

Utilization of wooden pallets with metal profiles represents a paradigm shift in the concrete block manufacturing industry. This innovative approach not only enhances efficiency and durability but also underscores the potential for synergy between traditional and modern materials in driving technological advancements.

As the demand for sustainable and high-performance construction solutions continues to rise, the integration of wooden pallets with metal profiles stands as a testament to the power of innovation in meeting evolving industry needs.

In the shipping, warehousing, and production of the block/paver block and curbstone, we as MEGA Wooden Pallet consistently prioritize giving our clients the highest quality and service.

Check our blog writing to learn more about The correct kiln-drying procedure.

Searching for cost-effective wooden pallets for your concrete block machine?

Cost-Effective Solutions for Your Concrete Block Machine

Looking for affordable wooden pallets without compromising on quality? MEGA Wooden Pallet has you covered. We offer a range of cost-effective pallet options designed to optimize your budget while ensuring reliability and performance. Trust us to deliver the highest quality and service for your concrete block machine needs.

Look no further than MEGA Wooden Pallet. We offer a range of cheap wooden pallet options without compromising on quality or performance. Our affordable pallet solutions are perfect for businesses looking to optimize their budget without sacrificing reliability or durability.

The cutting of the logs must be done precisely and correctly. Defects should be inspected, appropriately dimensioned and beveled after the log-cutting process.

The cutting of the logs must be done precisely and correctly. Defects should be inspected, appropriately dimensioned and beveled after the log-cutting process.