Types of Pallets for Concrete Block Machines: Types, How to Use and How to Maintain Them?

Choosing the right types of pallets for your concrete block machine is essential for ensuring smooth operations, durability, and cost-effectiveness. In this blog, we’ll explore the different types of pallets used in concrete block machines and provide tips on how to use and care for them to maximize their lifespan.

While ordering your pallet be sure that dimensions are well delivered to manufacturer.

Types of Pallets for Concrete Block Machines

-

Wooden Pallets

Wooden pallets are a traditional, cost-effective solution used in many concrete block machine operations.

- Strengths: They are eco-friendly, easy to customize, and simple to repair when needed.

- Applications: Wooden pallets are suitable for a variety of machines, especially for companies looking for sustainable options.

-

Wooden Pallets with Metal Reinforcements

These pallets combine the flexibility of wood with the durability of metal reinforcements.

- Strengths: The metal profiles provide extra strength, preventing warping and extending the lifespan of the pallet.

- Applications: Ideal for high-output machines where durability is critical.

When it comes to choosing the right pallet for your concrete block machine, wooden pallets stand out as a perfect balance of reliability, sustainability, and cost-effectiveness. These classic solutions may seem simple, but they offer unmatched flexibility and customization options that many other materials can’t provide. Their natural strength, combined with easy reparability, ensures they stay in top shape even with heavy use, giving you peace of mind and long-term value.

And here’s something even better—wooden pallets are an eco-friendly option. By choosing wood, you’re not only investing in a durable and adaptable solution, but you’re also supporting sustainable practices. Plus, if you’re working with us, you’ll get tailor-made designs to suit your machine perfectly, enhancing your productivity and efficiency.

So, why not choose wooden pallets? After all, it’s a decision that benefits your operations and the planet. Reach us for more details.

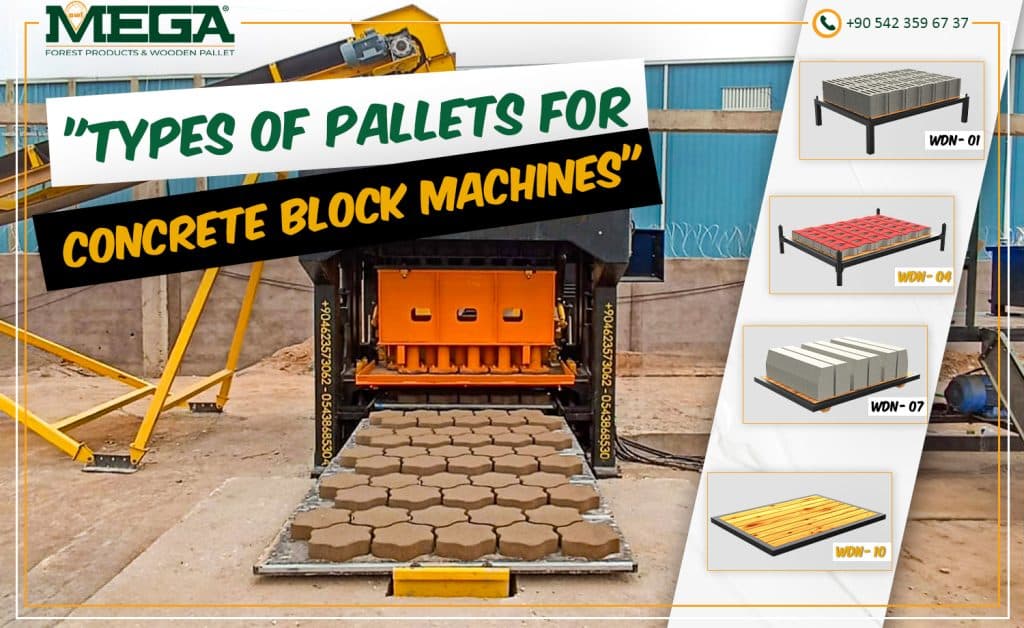

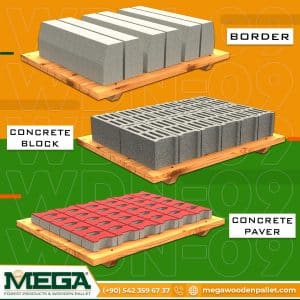

Types of Wooden Pallets That We Produce

We are producing wooden pallets, wooden pallets with metal frames, etc. for concrete block and paving block machines. The pallet quality is effecting the production rate of these blocks and their quality. While you produce the best products for the construction industry, we are committed to maintaining our premium quality.

At MEGA Wooden Pallets, we are dedicated to producing the highest quality pallets for your concrete block machines. Whether you need standard pallets or customized solutions, we’re here to help. Contact us today to find the perfect pallet model for your operation!

-

Polymer Pallets

Made from synthetic materials, polymer pallets are known for their lightweight and robust characteristics.

- Strengths: They resist moisture, chemicals, and wear, making them low-maintenance.

- Applications: Best for high-frequency, heavy-duty production environments.

-

Steel Pallets

Steel pallets are designed for operations that require the highest levels of durability.

- Strengths: Strong and resilient, though heavier than other pallet types.

- Applications: Suitable for extremely heavy loads or harsh environments.

How to Use Concrete Block Machine Pallets

-

Load Management

Proper load management is essential to avoid damaging your pallets.

- Proper loading: Ensure the blocks are evenly distributed to prevent overloading.

- Weight limits: Always adhere to the manufacturer’s weight guidelines to ensure pallet longevity.

-

Handling Practices

- Automated systems: Make sure the pallets are properly aligned with stacking machines to avoid damage.

- Manual handling: Use forklifts carefully to avoid unnecessary impacts.

-

Compatibility with Machines

Always ensure the pallet type and size are compatible with your specific concrete block machine model.

Pallet Care and Maintenance

-

Wooden Pallet Maintenance

- Regular inspections: Check for cracks, splinters, and loose boards. Promptly repair any damage.

- Kiln drying: Periodically kiln-dry pallets to avoid moisture damage.

- Storage: Store in dry areas to prevent warping or rotting.

-

Polymer Pallet Maintenance

- Cleaning: Regularly clean to prevent residue build-up.

- Temperature control: Avoid exposing polymer pallets to extreme heat or cold to prevent damage.

-

Metal-Reinforced Wooden Pallet Care

- Monitor metal profiles: Inspect regularly for rust or warping.

- Re-coating: Apply protective coatings to prevent corrosion.

- Repairs: Repair any bent or damaged metal parts immediately.

- Steel Pallet Care

- Rust prevention: Keep steel pallets dry and apply anti-rust coatings when necessary.

- Structural inspections: Check for dents or damage that could affect performance.

Benefits of Proper Use and Care

- Longevity: Proper maintenance ensures that your pallets last longer, reducing replacement costs.

- Efficiency: Well-maintained pallets help prevent production delays.

- Safety: Proper care reduces the risk of pallet failure, keeping your workplace safe.

Conclusion

By choosing the right type of pallet and following best practices for use and care, you can extend the lifespan of your pallets, increase production efficiency, and save on costs. Whether you opt for wooden pallets, metal-reinforced pallets, or polymer pallets, regular maintenance is key to ensuring smooth operations and a safer workplace.